Maximizing Efficiency: Unveiling the Power of Rotary Dryer Machines

In the world of industrial processes, efficiency is the cornerstone of success. When it comes to drying materials efficiently and effectively, rotary dryer machines emerge as indispensable tools. In this article, we delve into the multifaceted realm of rotary dryer machines, exploring their applications, advantages, and potential drawbacks.

What is a Rotary Dryer Used For?

Rotary dryer machines are versatile workhorses utilized across a spectrum of industries for drying various materials. From minerals and aggregates to agricultural products and chemicals, these machines play a pivotal role in reducing moisture content, enhancing product quality, and facilitating storage and transportation.

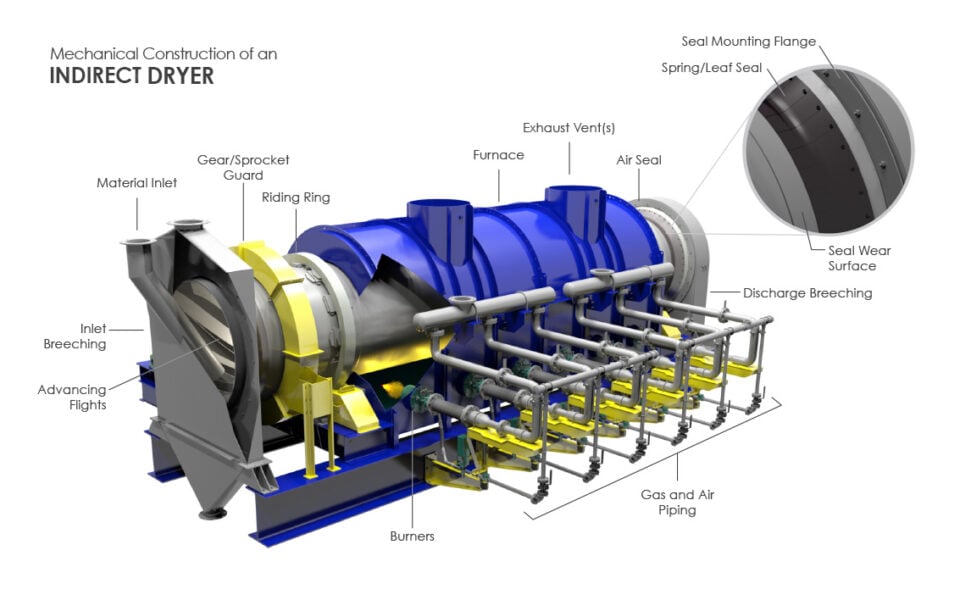

The mechanism behind a rotary dryer is elegantly simple yet remarkably efficient. Material enters the rotating drum, where it encounters hot air or gas flowing through the system. As the drum rotates, the material tumbles, ensuring thorough exposure to the drying medium. This controlled agitation maximizes heat transfer, expediting the drying process and yielding uniformly dried products.

Advantages of Rotary Dryer Machines

One of the standout advantages of rotary dryer machines is their adaptability to diverse materials and processing requirements. Whether dealing with fine powders, granular materials, or sticky substances, rotary dryers can accommodate a wide array of feedstocks, making them indispensable in industries ranging from mining to agriculture.

Moreover, rotary dryer machines boast exceptional efficiency, significantly reducing drying times compared to traditional methods. By harnessing the principles of convective heat transfer and mechanical agitation, these machines deliver rapid and uniform drying, translating into increased throughput and productivity.

Additionally, rotary dryer machines offer a compact footprint relative to their drying capacity, making them ideal for space-constrained facilities. Their modular design allows for seamless integration into existing processing lines, offering flexibility and scalability to meet evolving production demands.

Disadvantages of Rotary Dryer Machines

While rotary dryer machines offer an array of benefits, they are not without limitations. One potential drawback is the requirement for robust maintenance protocols to ensure optimal performance and longevity. Components such as seals, bearings, and drive systems may experience wear over time, necessitating regular inspections and servicing to prevent downtime and costly repairs.

Furthermore, rotary dryer machines may pose challenges when handling heat-sensitive materials or products prone to degradation at high temperatures. Careful process optimization and control are essential to mitigate the risk of product quality issues or thermal damage, necessitating meticulous attention to detail and expertise in dryer operation.

Exploring Genex’s Rotary Dryer Machines

At Genex, we take pride in engineering cutting-edge solutions that empower industries to thrive. Our Rotary Dryer Machine stands as a testament to our commitment to innovation, reliability, and performance excellence. With a robust design, advanced control systems, and unparalleled efficiency, our rotary dryers are tailored to meet the unique needs of diverse applications, ensuring optimal drying performance and product quality.

Conclusion

In the realm of industrial drying, rotary dryer machines reign supreme, offering unmatched versatility, efficiency, and reliability. While they present certain challenges, the benefits far outweigh the drawbacks, making them indispensable assets across various sectors. With Genex’s Rotary Dryer Machine leading the way, industries can harness the power of efficient drying to drive productivity, enhance product quality, and achieve operational excellence.

Ready to revolutionize your drying processes? Explore Genex’s Rotary Dryer Machine today and unlock a new era of efficiency and innovation.