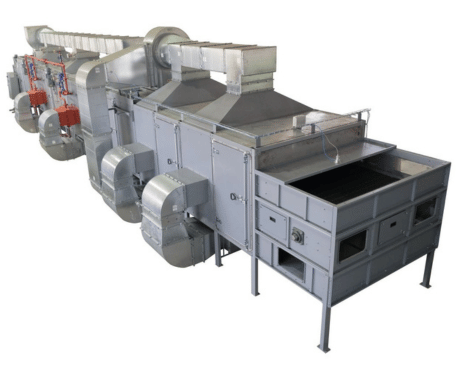

Belt Dryer

A belt dryer is a continuous drying system used to remove moisture from various substances or materials. It consists of a conveyor belt that transports the material through a drying chamber where heat is applied to evaporate the moisture. This type of dryer is commonly used in industries such as food processing, agricultural processing, pharmaceuticals, and chemicals, among others.

The design of a belt dryer typically consists of several key components:

- Conveyor Belt: The conveyor belt is the backbone of the dryer, responsible for carrying the material through the drying chamber. It is usually made of a durable material such as stainless steel or synthetic fabrics like polyester or PTFE (Teflon). The belt is designed to withstand high temperatures and tension, ensuring smooth and efficient operation.

- Drying Chamber: The drying chamber is where the material is exposed to heat to facilitate the evaporation of moisture. It is usually enclosed to prevent heat loss and to control the drying environment. The chamber may feature adjustable temperature and airflow controls to optimize the drying process for different materials.

- Heating System: Belt dryers employ various heating systems to provide the necessary heat for drying. Common heating sources include electric heaters, gas burners, steam coils, or infrared radiation. The choice of heating system depends on factors such as the type of material being dried, desired drying temperature, energy efficiency, and operating costs.

- Airflow System: Proper airflow is essential for efficient drying in a belt dryer. Air is circulated through the drying chamber to carry away moisture evaporated from the material. Some belt dryers use forced air circulation systems with fans to ensure uniform drying throughout the material bed.

- Moisture Control System: Maintaining precise control over the drying process is crucial to achieving the desired moisture content in the final product. Belt dryers may incorporate moisture sensors and control systems to monitor and adjust drying parameters such as temperature, airflow, and belt speed in real-time.

Benefits of Belt Dryers:

Continuous Operation: Belt dryers offer continuous processing capabilities, allowing for uninterrupted production with high throughput rates.

Uniform Drying: The conveyor belt ensures uniform exposure of the material to heat, resulting in consistent drying and uniform moisture content across the product.

Space Efficiency: Belt dryers have a compact footprint compared to other drying systems, making them suitable for installations where space is limited.

Energy Efficiency: Advanced control systems and heat recovery mechanisms help optimize energy usage, reducing operating costs and environmental impact.

Versatility: Belt dryers can accommodate a wide range of materials, including powders, granules, flakes, pellets, and even liquid slurries, making them versatile for various industries and applications.