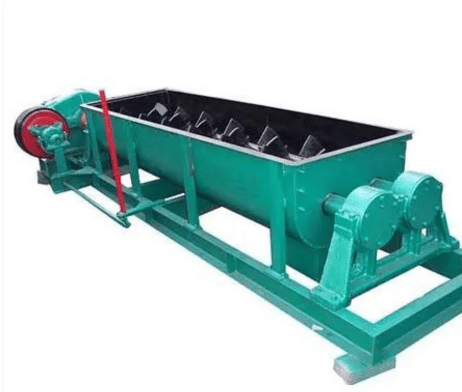

Mixer Machines

The mixing barrel is predominantly utilized in various sectors of metal mining for the purpose of blending materials and pharmaceuticals prior to flotation processes. Furthermore, it aids in the mixing of non-metallic minerals. It is particularly suitable for materials with concentrations below 30% and granularities less than 1mm, featuring a design reminiscent of a flattened barrel with helical runners facilitating material movement and mixing within.

The mixer boasts a compact structure with dependable sealing, complemented by an ash damper at the discharge gate to prevent the ingress of water and fog. Notable advantages include uniform mixing, a sector-shaped propeller, and a substantial contact area. Multiple rows of nozzles ensure the even distribution of water.

Prominent features include minimal ash residue and a bottom watershed design, ensuring overall cleanliness. The machine demonstrates advanced performance, maintaining consistent production quality, uniform mixing, and rapid discharge.

During operation, the impeller’s rotation induces circular motion within the tank, ensuring thorough mixing of pulp and pharmaceuticals throughout. Consequently, the blended suspension liquid is discharged through the overflow outlet.

The performance characteristics of Mixer Machines

- Compact structure and reliably sealing. Besides, there is an ash damper installed at the mouth of the discharging gate, which can prevent water and flog to enter in.

- It has advantages of evenly mixing, sector shape of propeller and large contacting proportion.

- There are many rows of nozzles, which can guarantee water to flow evenly.

Features Of Mixer Machines

- There is less ash left. Besides, there is a watershed set on the bottom. So the whole machine is very clean.

- Advanced equipment performance. The quality of production is stable. The mixing is even. And the discharging is quick.

Working process of Mixer Machine

When the machine works, the pulp and pharmaceutical take circular motion by the rotation of the impeller to get mixed evenly in the whole tank, and then the mixed suspension liquid discharges from the overflow part.